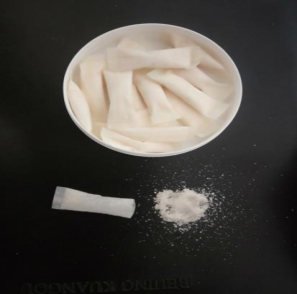

Nicotine Pouches: This small fiber bag can be placed directly between the gums and upper lip to absorb nicotine. This product does not contain tobacco and does not require spitting out residue or burning, providing users with a new and convenient way to ingest nicotine.

Nicotine pouches are mainly popular in the Nordic region, such as Sweden, Norway, Denmark and other countries. In addition, there are also consumer markets in Russia, the United States and other countries.

According to the latest research report of market research and consulting company Maximize Market Research Pvt Ltd, the global nicotine pouch market is expected to reach nearly US$23.6 billion by 2030, and the industry will have an astonishing compound annual growth rate of 35.8% between 2024 and 2030, with broad market prospects.

Common types of Nicotine Pouches

Generally, they are made of a mixture of granules or powders. According to the different water content, they are divided into three types: dry method, semi-dry and semi-wet method, and wet method; according to the humidity, they can be divided into low-humidity products: humidity within 8%; medium-humidity products. Humidity is 8%-25%.

There is also a type of high-humidity product: if the humidity is above 25%, especially in Europe, this high-humidity product market accounts for more than 80%. High-humidity products have the characteristics of fast head and strong throat hit, but high-humidity products have too high moisture content and poor fluidity when packaged in granules, resulting in large loading volume and uneven finished product content. The packaging process is not smooth and the feed pipe is often blocked, resulting in low production efficiency.

The dry method is represented by ZYN, with a moisture content of less than 3%:

Semi-dry and semi-wet is represented by FEATX, with a moisture content of 3-8%:

The wet method is represented by VELO, and can be further divided into low-humidity products (humidity between 8-10%), medium-humidity products (humidity between 8%-20%) and high-humidity products (humidity above 20%):

Nicotine pouch production process

Process:

Granulation → Automatic box sorting → Pouch making → Counting cans → Box sorting → Capping → Labeling → Heat shrink packaging → Collection

1. Weighing

Different weighing methods are adopted according to different requirements (such as taste, coolness, sweetness, etc.);

nicotine pouch composition includes nicotine, sugar alcohol, pH regulator, filler and flavoring agent, etc.

2. Granulation

After mixing powder, flavor, nicotine liquid, aqueous solution and other materials with adhesive, they are moved in annular, radial and axial directions under the action of a modified agitator, fully mixed, and then cut into uniform and dense spherical particles (the particles seen in nicotine bags) by a granulation cutter.

Granulation methods: wet granulation, dry granulation, one-step granulation, spray granulation, among which wet granulation is the most widely used.

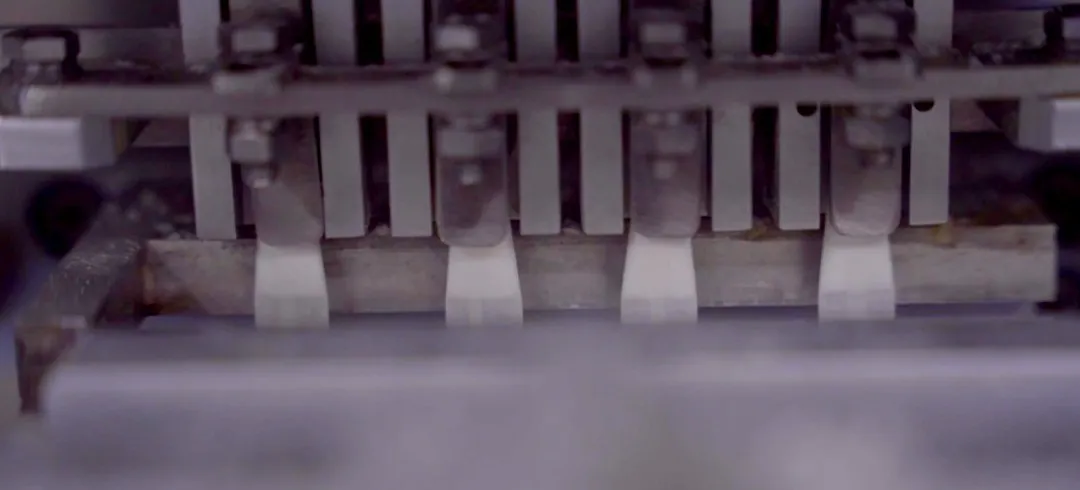

3. Pouch Making

The powder (the granules prepared in step 2) is fed into the hopper above the packaging machine by a feeder. The packaging speed is controlled by a photoelectric positioning device. The rolled non-woven fabric is driven by a guide roller and introduced into the collar former. After being bent, it is overlapped into a flat shape by a longitudinal sealer. The material is automatically measured and filled into the prepared pouch.

The transverse sealer intermittently pulls the pouch tube downward while performing heat sealing or ultrasonic cutting, and finally forms a flat pouch with overlapping longitudinal seams and three-sided sealing, completing the sealing of a bag. The PLC automatic control system is used to accurately complete the measurement, filling, sealing and other tasks.

4. Packaging

Package into boxes according to needs; boxes are generally divided into several types, the most common ones are PP boxes with a diameter of 7CM.

Generally:

15 pouch/box (cans),

16 pouch/box (cans),

18 pouch/box (cans),

20 pouch/box (cans).

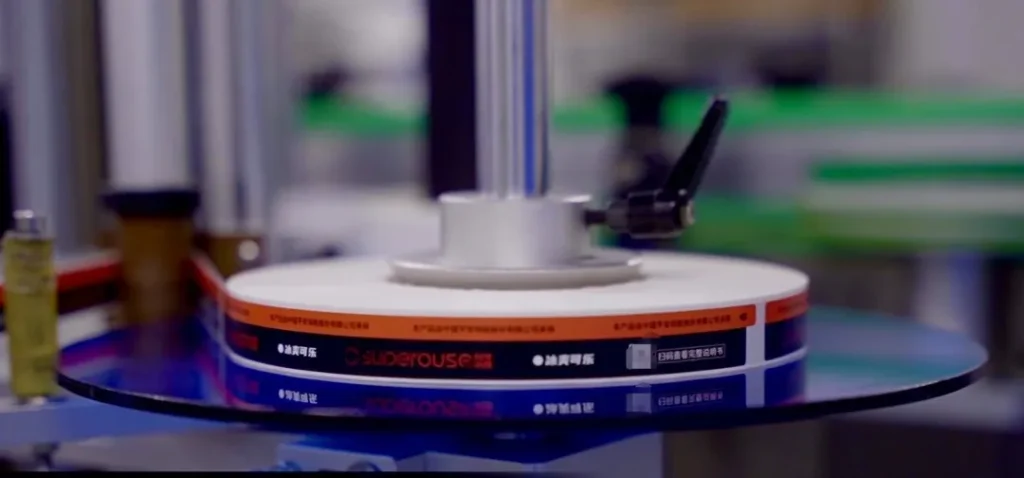

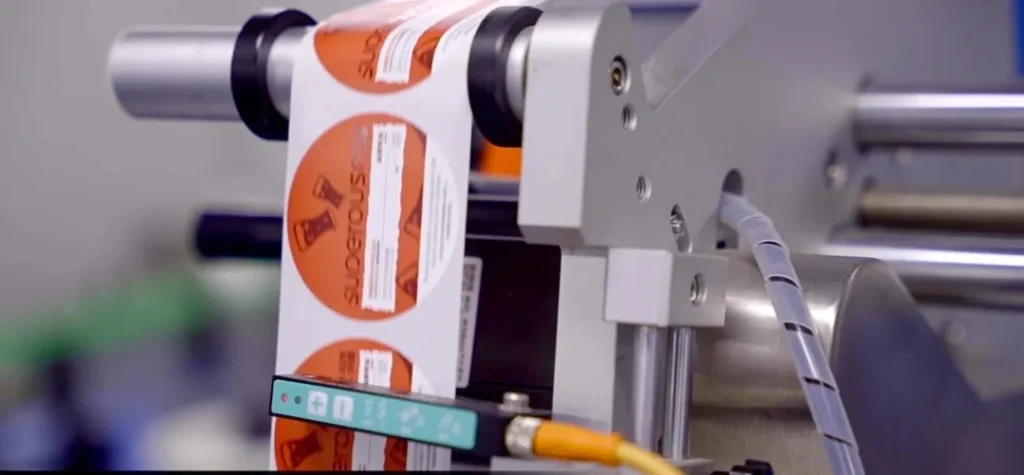

5. Labeling

Different brands have different labels; round boxes are usually labeled on the front, back, and sides.

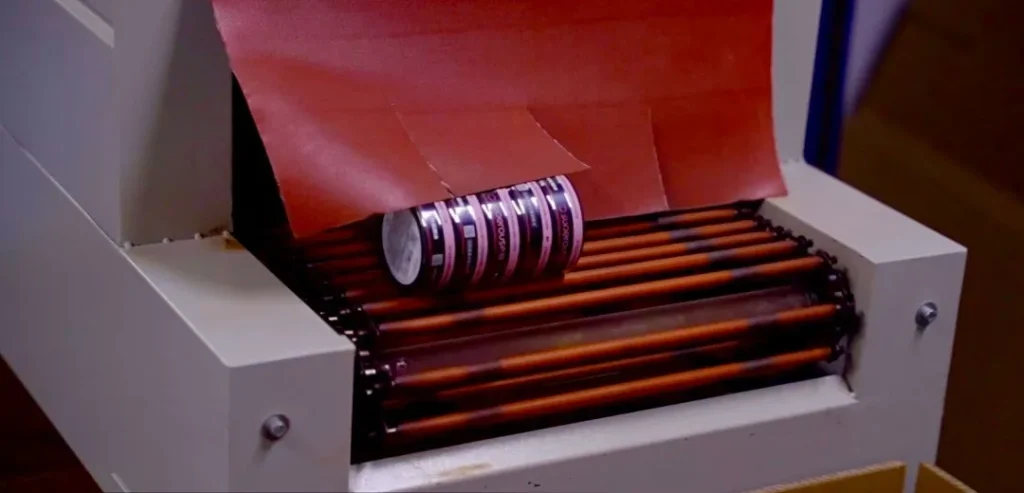

6. Plastic packaging

Different brands have different requirements, usually 5 boxes/barrel, some 10 boxes/barrel.

Dry Process vs Wet Process vs Oil Process

Dry

- Nicotine Pouch moisture content is not higher than 4%

- The American market prefers

- It takes one to two minutes to enjoy the nicotine and taste experience. It is less irritating to the gums, fits better with the gums, absorbs slower, and is more sustainable

- The product has a longer best life, usually two years.

Wet

- The moisture content of Nicotine Pouch is about 15%-30%

- Suitable for softer, smaller bags, currently mainstream

- The speed of releasing nicotine is much faster, and the top feeling will be produced within tens of seconds. It is fast on the head and has strong absorption. It can quickly achieve the feeling of nicotine satisfaction, but the release of nicotine is more stable

- The product has an optimal shelf life of one year.

Oil

- Features of this type of product: Oily particles, not easy to deteriorate. Nicotine is highly stable and not easy to hydrolyze.

- Divided into: low moisture load products within 6%; high moisture load products 10-20% (forming loose gelatinous blocks, like brown sugar, will dissolve in the mouth)

- ICE product features Advantages of this type of product: The shelf life is generally 18 months, and the irritation of the product is between (dry particles and wet particles) and the main market for this type of product is the United States and Europe.

Nicotine pouches are currently divided into two types: dry and wet. Wet bags have a higher moisture content, while dry bags rely entirely on saliva to stay moist.

We are well aware that in this rapidly changing market, only continuous innovation can meet consumers’ demand for healthy and environmentally friendly products. Therefore, ZON continues to invest in research and development, using the latest scientific and technological achievements to provide our customers with high-quality and diversified nicotine pouch products. Our products are tobacco-free, reducing the impact on the environment, while providing a variety of flavors and nicotine concentration options to meet the personalized needs of different consumers.

In addition to maintaining close cooperation with major international brands, ZON also attaches great importance to its partnership with small and medium-sized brands and buyers. We believe that by cooperating with brands of all sizes, we can better meet the diversified needs of the market and promote the development of the entire industry. We provide flexible customization services and competitive prices to support the growth of small and medium-sized brands and market expansion. In this rapidly changing market, ZON is willing to work with you to open up broader market prospects.